Why you should choose True Refrigeration’s upright cabinets

Electricity costs have always figured significantly into the overall profit and loss of a foodservice operation but the accelerating rise in prices has caused a sense of urgency in finding solutions to reduce energy consumption.

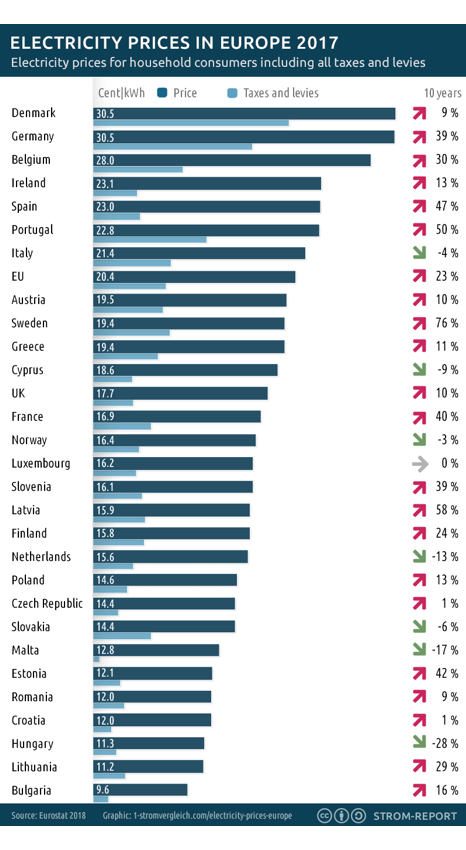

In one recent study more than 40% of an average commercial kitchen’s electricity costs are attributed to running the site’s refrigeration systems. The average EU consumer of electricity saw an average 23% increase in electricity prices from 2007 – 2017; countries such as Germany and France have seen increases of 40% with Swedish consumers paying a massive 76% higher electricity prices since 2007.

The price of electricity in European countries

The goal of reducing energy consumption in foodservice operations must be balanced with an equally-important task: ensuring correct, consistent holding temperatures for food products, especially in hot kitchens during the warm summer months.

Choosing refrigeration products that use the least amount of energy but are unable to maintain proper food temperatures can result in spoiled products and even foodborne illness outbreaks—the last thing that any foodservice operation wants to face. So where does a fine-dining restauranteur or food truck operator turn to for sensible refrigeration solutions to achieve both goals?

True is the undisputed industry leader in the development and use of hydrocarbon (HC) refrigerants in its products. For the past ten years, True has invested heavily in research and development of R290 systems in order to promote sustainability and lower the overall cost of operation over the average lifespan of a refrigerator or freezer.

Today, some 85% of True refrigerators and freezers of all categories run on R290 refrigerant. The transition is scheduled to be complete by 2021, ahead of all other major commercial refrigeration manufacturers worldwide.

One outstanding example of R&D efforts is True’s new GN-compatible counter refrigerators and freezers, bar none the most energy-efficient counters in its class. Earning an A+ rating with the lowest energy consumption used per year in kilowatt hours, True counter refrigerators save foodservice operators big money year-after-year while maintaining proper and consistent holding temperatures needed to maintain food safety.

No other manufacturer currently comes close to our standards.

Another example of True’s innovation is the development of True’s new glass door visual merchandisers which also use R290. In many establishments, the best way to increase food and drink sales is to make products easily-accessible for customers to self-service or ‘grab-and-go’. For years, air curtain display refrigerators were the standard for this application, yet they also require a tremendous amount of energy input to run.

True’s TVM series features low energy yet brightly-lit LED lighting and energy-efficient glass doors for easy access of products inside. Best of all, TVM glass door merchandisers use far less energy to run, up to 84% less compared to traditional air curtain units of the same size and footprint.

True’s TVM-48SL visual merchandiser at the Beermerchant’s Tap in London

R290 technology in True refrigerators and freezers simply make sense. Lower energy costs, protection of the environment, still maintaining consistent, proper holding temperatures, even a simpler way to perform necessary service repairs… are all the result of True’s commitment to creating a better, more sustainable way to cool or freeze food products.

If you would like to find out more about True’s energy efficient refrigeration solutions contact us today.