Why you should choose True Refrigeration’s upright cabinets

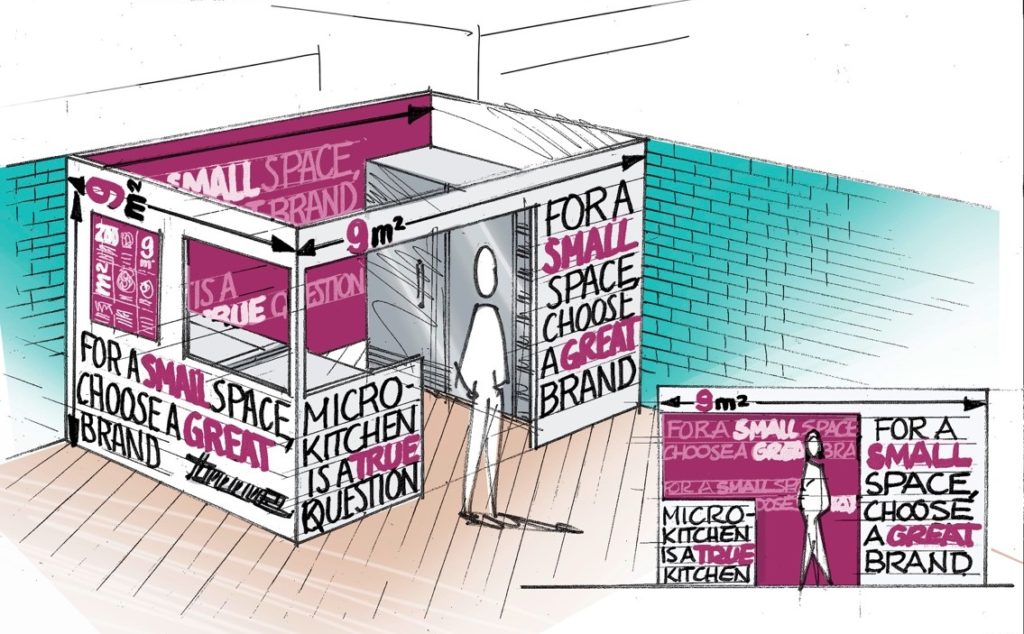

For a while now, there has been an ongoing trend for shrinking commercial kitchen space. This is especially true in busy European city locations, where fixed building sizes and spiraling rent costs are constantly forcing operators to increase profitability.

One way of doing this is through a larger and more elaborate front-of-house, increasing the number of covers or the size of the bar to accommodate more custom, but it is often the back-of-house which has to downsize as a result.

The ratio for kitchen size to the number of covers was traditionally 40% back-of-house to 60% front-of-house, but increasingly, this is no longer the case.

While rent costs and a more general lack of space in busy city locations are driving factors, the consequences of this shift aren’t all necessarily bad for kitchen operators. Less space to move around can result in increased operational efficiency, minimizing staff movements outside their key workstations.

Equipment manufacturers are also developing their offering to accommodate this requirement, with an increasing number of smaller footprint and more multifunction products available, such as combi ovens and reduced size refrigeration units for spot placement.

It isn’t just brick and mortar restaurants that are adapting to space restrictions. Operators, such as food trucks, shop-in-shop concession & kiosk vendors, and “pop-up” concepts are naturally limited in space.

Small footprint outlets like these are an obvious choice for new start-ups and proof-of-concept offerings, and we’re seeing a developing trend for things like shipping containers being converted into restaurants.

This is a fantastic budget and eco-friendly option that new and established operators are jumping on, following the success of concepts like Boxpark. The prefabricated modular design and durable construction of a shipping container is a great “building block” for a small-scale F&B offering, and can be highly customized in terms of the internal layout and external look.

Shipping container restaurants are great for customization.

New and restricted-budget businesses operating out of a small footprint location may be naturally inclined to wonder if domestic refrigeration equipment would be suitable for their requirement. After all, there is a wide range of whitegoods available, often in smaller sizes than fully commercial offerings, and at a lower price.

For commercial operators, this is not a recommended course of action. Domestic refrigeration units are unable to maintain food-safe temperatures when doors and drawers are being accessed frequently, or in high ambient conditions. They simply aren’t designed to stand up to the rigors of commercial operation.

Fortunately, there are now fully commercial refrigeration solutions with small footprints available, and most equipment retailers offer financing and leasing options so that any operator is able to access the essential equipment they need for a low recurring cost.

In response to these evolving requirements, True has developed additional products with smaller operational footprints that still maintain our highest standards for temperature provision, allowing space-restricted commercial operators to maximize operational efficiency.

Small footprint outlets are ideal for coffee, fresh lunch, and juice retail.

For front and back-of-house applications, these products include solutions for refrigerated storage, preparation, and premium product display.

Our new T-11G-HC~FGD01 is a super slimline upright display unit, featuring a width of just 487 mm and a depth of 539 mm. Designed for storing and showcasing premium chilled products, such as cold-pressed juices, at or near the point of sale, the T-11G features an environmentally friendly R290 hydrocarbon refrigeration system that steadfastly maintains strict cabinet temperatures 0.5°C to 3.3°C.

True’s new T-11G-HC~FGD01 is a super slimline upright refrigerated display solution.

Restricted space also means equipment should be more multifunctional and versatile. True’s TSSU prep tables are a great example of this, combining refrigerated storage with easily accessible chilled food pans, and a cutting board surface for meal prep.

Our TSSU-27-08-HC is the smallest unit in the range, ideal for fresh and gourmet sandwich operators, with configurable food pans and a strict holding temperature range, not exceeding 5°C. The product has recently been redeveloped, now powered by True’s energy and environment-friendly Natural RefrigerantÒ system, and requiring zero space clearance to the unit sides, ideal for side-by-side placement and “built-in” applications, where available space is restricted.

Counter refrigerator products are also a great option where space is at a premium, typically featuring a solid stainless steel top which can be used for prep, or in some cases, situating other equipment on top.

Our TUC-24-HC is a small footprint undercounter featuring a fully commercial “forced air” refrigeration system, unlike many similar sized products on the market. Rated ‘A’ in terms of energy efficiency and ‘Climate Class 5’ for operation in even the most demanding kitchen environments, the small unit still features a full 98ltr net capacity, significantly larger than other products with a similar footprint on the market.

Are you feeling restricted in your kitchen? Maybe you’re looking for some help or advice on kitting out a new pop-up?

Our cold storage experts are available to discuss any refrigeration requirement you might have, and we work with designers, suppliers, and project management companies across the industry who can help you take your project from concept to realization.

We look forward to hearing from you.