Why you should choose True Refrigeration’s upright cabinets

We all want to enjoy long and productive lives. The way we see things at True Refrigeration, the same should go for commercial refrigeration equipment.

Like any major capital expenditure, maximising the effective operational life of your commercial refrigeration equipment is smart business. Today, the average life expectancy is around 10 years per unit. But just imagine if you could extend that. Every additional month – or even year – you can delay your next purchase directly benefits the bottom line.

From the smallest of preparation counters and display cabinets to the largest of fridges and freezers, they may seem sturdy compared to a lot of equipment in your business – and, in many ways, they are – but they still need to be looked after. In no particular order, here are six of the key things that make the biggest difference, based on our decades of experience as a global refrigeration leader.

It may seem obvious. But when you run a busy kitchen it’s all-too-easy to overlook this vital activity. Quickly clean up any spills (inside and out), avoid dust build up and always make sure the drain pan at the bottom of your refrigeration units aren’t building up with excessive condensation. Cleaning the condenser coil and evaporator every month could also help you significantly extend the unit’s lifespan and operating efficiency. Dirty coils can force the condenser fan motor to work much harder, decreasing its effective lifespan.

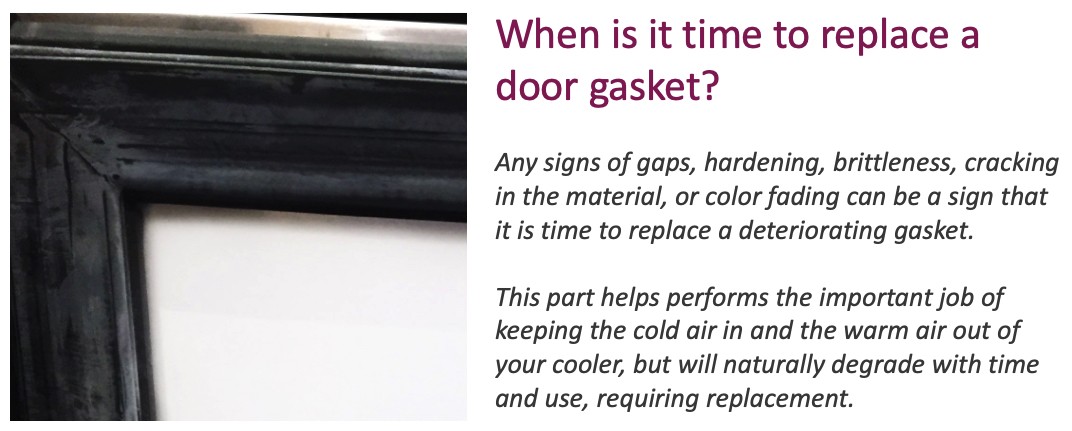

Commercial refrigerators and freezers are only as good as the quality of their seals, or gaskets. For optimal cooling performance and energy efficiency they must be air-tight. This means regular checks are essential. If even a small amount of cool air is escaping through gaps or cracks, the compressor will need to work much harder to maintain a constant temperature. Not only will this increase your energy bills, it may eventually cause premature component failure. If there are any issues with your seals, have them replaced as quickly as possible.

Yes, there’s a cost involved to have your refrigeration equipment serviced. But have no doubt, a little care on a regular basis remains one of the best ways to prevent far more expensive downtime and major servicing down the track. In almost all cases, neglecting proper maintenance will eventually lead to unnecessary wear on components, increased energy consumption and shortened operational life.

It may be tempting to try and save money by ‘going it alone’, but our advice is to always have your equipment serviced by a fully trained and accredited technician. They’re the experts who know your equipment best – and they’ll also have the right tools for the job.

This one may sound a little strange, but it can make a real difference. The high levels of acidity in many popular foods (tomatoes and pickles are frequent offenders), coupled with the inevitable spills that happen in and around commercial kitchens, can do real damage to the coated surfaces and seals in fridges and freezers, and even cause corrosion. Always keep your food and ingredients properly covered and sealed.

Just like a car, there will inevitably come a point where the costs of repairs and maintenance begin to outweigh the benefits of keeping your existing equipment. Hopefully by following the previous five tips that’s still many years away. But when the time does come, it’s important to recognise it. There’s no point throwing good money after bad.

The good news is, like many industries, technology moves fast in the world of commercial refrigeration. After 10+ years you’ll almost certainly be able to get a replacement system that’s far superior to your previous one – with greater performance, energy efficiency and features.

Want to maximise the life of your commercial refrigeration equipment?

Contact True Refrigeration today